Frequently Asked Questions

How does a pressure washer make things clean?

Understanding the cleaning process is essential to the effective use of a pressure washer. A pressure washer cleans by creating a high pressure stream of water that hits the surface with a large amount of kinetic energy, thus removing the dirt mechanically, while providing a constant flow of water to wash the dirt away. Often dirt is mixed with grease or oil, or other substances, which chemically bond the dirt to the surface you are trying to clean. Sometimes even the force of high pressure water needed to break these chemical bonds is insufficient to get the surface clean without requiring excessive pressure, that is either impracticable or would damage the surface. Adding a detergent, or other cleaning chemical, or using hot water, while agitating or brushing the surface, significantly enhances the cleaning power of the pressure washer.

Detergents and soaps are used for cleaning because pure water can't remove oily, organic soiling. Soap cleans by acting as an emulsifier. Basically, soap allows oil and water to mix so that oily grime can be removed during rinsing. Detergents cannot accomplish much until some mechanical energy or agitation is added into the equation. This mechanical energy is provided by the pressure washer. As the detergent emulsifies the grime, breaking the chemical bond, the blasting effect of the pressurized water strips the dirt from the surface, while the flowing water rinses the detergent and soil away. Warm or hot water, or steam, melts fats and oils so that it is easier for the soap or detergent to dissolve the soil and pull it away into the rinse water.

What is a pressure washer?

A pressure washer is a mechanical device that uses a pump to generate a high-pressure stream of water to clean surfaces. The pump is typically powered by a gasoline engine, an electric motor, or a diesel engine. The pump is a positive displacement pump that forces a specific amount of water flow from the outlet. By restricting the flow with the nozzle, much like you do by placing your thumb over the end of a garden hose, the pressure washer produces pressure. Without the nozzle the impact of the water from the end of the pressure washer hose is similar to that from a garden hose. The narrow diameter of the nozzle increases the water's velocity and, consequently, its impact and cleaning power. The smaller the nozzle orifice, the more pressure is potentially produced. However to produce greater pressure, more horsepower is required to force the water through the smaller hole. Each pressure washer calls for a specific size nozzle to match the flow of the pump and the horsepower of the motor. Putting too small a nozzle on your pressure washer strains the components and may cause excessive wear to the machine; too large a nozzle sacrifices cleaning power.

All pressure washers produce pressure and flow. Both are important to the cleaning process. Most pressure washers also provide a method for dispensing soap or detergents, either under low or high pressure. The proper use of soap is often key to the cleaning process. Hot water pressure washer are equipped a burner system to continuously heat the stream of water, further aiding the aiding the cleaning process. Most hot water pressure washer can generate wet steam of approximately 240 degrees F, by turning down the pressure to around 150 PSI. There also true steam cleaners that generate a dry steam of approximately 320 degrees F at 150 PSI. Understanding the basic concepts of pressure flow and cleaning units will help you pick the right pressure washer for the cleaning job at hand.

How important is pressure and flow?

Pressure washers use the impact of the water to break the bond of the dirt to the surface you are trying to clean; the higher the pressure, the greater the impact. The type of nozzle you use makes a huge difference in how much impact your pressure washer creates. A zero degree tip gives you the full impact of your pressure washer but is almost useless for cleaning because it hits such a small area. A 15 degree nozzle increases the area you can clean at one time, but reduces impact by 70%. A 40 degree increases the surface area cleaned further, but has 88% less impact than a zero degree nozzle. This is why a turbo nozzle is so effective; for it is a 0 degree nozzle rotating thousands of times a minute creating a 25 degree cone of full impact.

The amount of water, or flow, a pressure washer puts out makes a big difference in cleaning. The flow is what carries the impact to the surface. The more flow, the more impact; there is a direct relationship. A 13 HP pressure washer putting out 4000 PSI at 3.5 gallons a minutes flow has one third less impact than a 20 HP unit putting out 3,500 PSI at 5.0 gallons per minute. Moreover, flow is what is needed for effective rinsing. This is especially true when cleaning large open surfaces, like driveways; or quickly rinsing vehicles in truck washing operation.

What are cleaning units?

A pressure washer pump creates a positive water flow, and by restricting that flow at the nozzle creates pressure. The more horse power driving the pump allows more flow to be pushed through the pump and the more pressure to be created at the nozzle. For a given amount of horsepower you can have only so much pressure and flow; there is a tradeoff. Most people focus on pressure (PSI), but you really need to consider both pressure and flow. One way of comparing pressure washers is to use the measure of “cleaning units”. To calculate cleaning units, multiply the pressure times the flow of the pressure washer. All other things being equal (i.e. chemical use and heat) a unit with higher cleaning units will clean better than a unit with lower cleaning units.

Cleaning unit application guidelines

Home use, light duty: 2,000 to 3,750 cleaning units.

Medium duty: 3,800 to 7,500 cleaning units

Heavy duty: 7,600 to 15,000 cleaning units

The measure of cleaning units is a good way to compare the power of one pressure washer relative to another, with the following proviso. When two pressure washers have different pressure and flow specifications, but the cleaning units are equal, remember the unit with the higher pressure unit will make a rotary nozzle work better, while the higher flow unit will rinse better and make flat tip nozzles work more effectively. With that in mind, the following guide can be used on how much pressure and flow is needed to perform certain tasks. Some of these tasks may require a rotary Dirt Killer nozzle as well if you are using the minimum PSI. The minimum specifications are what are required to get the job done. Having more pressure and flow will make the job go faster. The column marked preferred CU shows how much cleaning power is required to get the job done more quickly. (CU means Cleaning Units: cleaning units = Pounds per Square Inch of pressure (PSI) times Gallons Per Minute of flow (GPM).

| Task | Min PSI | Min GPM | Min CU | Preferred CU |

|---|---|---|---|---|

| Wash a car | 1000 | 1.5 | 3,000 | 5,000 |

| Deck | 1500 | 1.5 | 2,250 | 7,000 |

| House | 1000 | 1.5 | 1,500 | 7,000 |

| Boat | 2000 | 1.5 | 3,000 | 7,000 |

| Barnacle removal | 3000 | 2.5 | 7,500 | 12,000 |

| Surface clean | 1500 | 3.5 | 5,250 | 15,000 |

| Brick | 2000 | 2.5 | 5,000 | 8,000 |

| Heavy Equipment | 1500 | 2.5 | 3,750 | 8,000 |

| Drives and sidewalks | 1,500 | 1.5 | 2,250 | 12,000 |

| Paint prep | 2,000 | 1.5 | 3,000 | 7,500 |

| Fleet wash | 1,500 | 3.0 | 4,500 | 8,000 |

| Graffiti removal | 3,000 | 3.0 | 9,000 | 12,000 |

| Parking lots | 2,500 | 3.5 | 8,750 | 14,000 |

How to select the right pressure washer?

For home use

If you will only use this pressure washer under 100 hours per year you can invest in a less expensive pressure washer. This is usually a cold water unit that can be a small gas (1,500-2,700 PSI, or 5.5 HP or less) or small electric (1,000 PSI - 1,500 PSI, 15 amps, 110v.).

Market research data shows that the average homeowner will use a pressure washer on average only about a maximum 20 hours a year. That works out to about 2 hours a weekend throughout the summer and a couple weekends in the fall and spring. With this in mind, most consumer units sold are designed to last about 250-400 hours and to meet a price point that the consumer will find acceptable. To meet this design criteria the pressure washer uses cast aluminum heads, plastic parts, and many integrated parts to keep assembly cost down. These less expensive components mean a lower price. (Commercial and industrial grade units have brass pump heads, steel and brass internal parts). However, if a problem develops the repair cost of these consumer pressure washers often exceeds the purchase price. These types of pressure washers are available through a variety of outlets: mass merchants, discount hardware stores, the web, mail order and specialty pressure washer stores. Remember, warranties are restricted and very limited when a home unit is used commercially.

For professional use

If you plan to use this pressure washer for 100 hours to 1,000 hours per year you need a commercial pressure washer. These pressure washers use brass heads and are much more durable than the consumer line by a significant factor, but do not have the capabilities or durability of the most industrial pressure washer units. Commercial grade gas units use direct drive systems to reduce the number of components, and hence the price of the unit.

Industrial pressure washers are specifically designed for the heavy-duty user (1,000 to 2,000 hours per year) in tough environments. As such they use the best quality components, such as forged brass pump heads, stainless steel valves. These units are designed to operate eight hours per day every day of the week. Industrial gas machines will either have belt-drive systems, or gear-drive systems, while electric pressure washers should use either 1600-1800 RPM TEFC (Totally Enclosed Fan Cooled) motors. Remember, it is important to select a unit with top quality components throughout, and not just focus on the power plant. The unloader valve that regulates the pressure causes most pressure washer problems. Yet many people never consider the quality of the unloader when making their buying decision.

Do I need hot water or cold?

Cold water

Cold water pressure washers can be used to successfully clean many objects and surfaces through a combination of impact of the spray and the application of cleaning chemicals and soaps. To maximize the cleaning potential of a cold water pressure washer you can use specialty accessories, such as a rotary nozzle; or for large open areas, a flat surface cleaner. No matter what nozzle you use, selection and application of the correct cleaning chemical can make a tremendous difference. Cleaning chemicals are formulated in different ways for different applications. Make sure you are using the best chemical solution for your application.

Hot water

We know from washing dishes that hot water makes cleaning easier, especially if we are cleaning greases, oils, or petrochemicals. Cold water can only be as effective if the proper cleaning chemicals are also used. Hot water can often make cleaning up to 50% faster by loosening dirt, gum, grease and oil. Most water units consist of two power systems: the pump-motor to create the high-pressure water, and the burner-coil to heat the stream of pressurized water. The pump-motor can be can be gas or electric powered. The burner-coil system the unit requires electricity to run the burner motor while burning kerosene or diesel oil to heat the pressurized water in the heavy-duty heating coil. If the hot water unit is electric powered, you use the same electricity to power both the pump-motor as well as the burner-coil. However, you still burn diesel or kerosene for fuel to heat the water. If the unit uses a gas engine to power the pump, you still need electricity to power the burner-coil. So unless the unit uses a self-contained power source such as a battery or generator, you have to plug the hot water unit into an electrical source. Because of the extra weight of the heating coil and burner system, a hot water unit is much heavier, more complex, and more difficult to maintain than a cold water unit.

How much pressure and flow do I need?

Around the house

To clean around your house, wash your siding, wash your car, or clean your deck, you only need 1,500 to 2,000 PSI. If you use a rotary (Dirt Killer) nozzle you can quickly handle even tougher jobs such as mold or mildew removal with this size pressure washer. For concrete cleaning or to clean barnacles off boat hulls you would be better off with 3,000 PSI.

Professional use

As a commercial contractor you need at least 2,500 PSI in order to be fully productive. The cleaning impact of pressure can be increased significantly by use of rotary (Dirt Killer) nozzles. These nozzles can effectively cut cleaning time of hard surfaces in half. Make sure you have enough flow. Flow is important for rinsing horizontal surfaces or powering surface cleaning machines. If you are cleaning vertical surfaces, or excess water is a problem, a low flow/high-PSI unit with a rotary nozzle is probably a better solution. This is because Dirt Killer nozzles work better the higher the pressure; (flow is a less important to make Dirt Killer nozzles effective).

Based upon these factors a commercial cleaner would want a machine with at least 3,000 PSI and 4 GPM, to be able to handle a wide variety of cleaning problems. You have the pressure to clean, and the flow to rinse. For a given amount of horsepower you can only get so much pressure and flow. Traditionally, before the advent of rotary nozzles, to get more cleaning impact you needed more pressure and more flow. Pressure is good for cleaning, but remember fan spray nozzles spread out the impact of the pressure, so more flow keeps impact high; plus, to rinse you need flow to push the dirt across the horizontal surface. Now with rotary (Dirt Killer) nozzles, a smaller pressure washer can give you more cleaning impact. If you just need cleaning impact, and rinsing action is less important, such as in paint preparation or asbestos removal, go with a high-PSI, low-flow unit, to keep your horsepower and cost factors down. If what you are cleaning comes off easily, but you need to push a lot of dirt -- for example, cleaning animal enclosures -- then you need a high rinsing or high-flow unit with at least 3.5 gallons per minute.

What are some of the other factors in picking a pressure washer?

The first step in picking a pressure washer is determining what performance you need to get the job done. How much pressure? How much flow? Do you need hot or cold water? Once you have decided upon these factors, discussed in the other sections, you can focus on whether a gas or an electric unit best suits your needs. Either gas engines or electric motors can power a high pressure cleaner by a variety of drive systems. The different combinations have advantages and disadvantages.

Electric powered pressure washers

Electric units are quiet and do not consume fuel, nor do they pollute or put our fumes. The disadvantage of electric units is that the electrical circuits commonly found in a home are rated only for 110 volt, 15 amps and, therefore, do not provide much power -- about 1.5 HP or about 2,500 cleaning units. Industrial electrical 110-volt circuits are 20 amp, and thus put out about 2 HP of power or about 3,600 cleaning units. To get more power, an electric motor must run on a 220-volt or 440 volt circuit. These types of circuits are only found in industrial settings. On these larger units you can get 5 HP or 7.5 HP pressure washers or 8,000 plus cleaning units.

The three types of gas drive units

Gasoline powered units have the advantage of putting out larger horsepower no matter where you are located. However, the fuel is more expensive, and you have the problem of noise, and fumes - making them impractical to use indoors. Gas units have different types of drive systems.

Direct-drive gas pressure washers

In direct drive systems, the pump is connected directly to the engine. So the pump spins at the same speed as the engine -- typically 3,600 RPM. This system has the advantage of being simple, with few moving parts, and therefore is less expensive. The disadvantage is by having the pump spin as much as the engine the bearings get more wear and tear, reducing the life span of the pump.

Belt-drive gas pressure washers

Belt-drive units use pulleys and belts to slow the speed of the pump. Where the engine spins as 3,600 RPM the pump will be slowed from 1,100 to 1,600 RPM depending on the pulley and belt set up. This system ensures long pump life because the bearings do not get as much wear and the pump is isolated from the heat of engine, being separated by the belts and pulleys. The disadvantage of this system is there is some loss of efficiency due to the additional friction from the belts and pulleys. Plus there is more maintenance required adjusting the belts.

Gear-drive gas pressure washers

Gear drive systems come in two styles. Some like the Dirt Killer and KränzleUSA lines use Honda gear-drive engines with a wobble plate pump. Other manufacturers use a standard gas engine with an extra gearing component mounted between the engine and the pump crankcase. Both of these systems reduce pump speed in half by means of the gears. This increases the pump life by saving wear and tear on the bearings. Of the two systems, the Dirt Killer and KränzleUSA system that uses Honda gear-drive engines with the wobble plate pump is the most efficient and durable for the following reasons. 1) It has the fewest moving parts; the gears are part of the Honda engine so there is no extra oil seal between the pump and the separate gear component. 2) The wobble plate system smoothly transfers the power from the engine in one axis, instead of two like a crankcase pump.

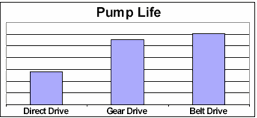

The pump life chart is a rough way of comparing the average pump life of the different gas drive systems based upon how much the pump spins over the life of the system. All other things being equal, the slower the pump spins, the longer the pump will last due to bearing life and the wear and tear on internal parts. The way the pump is used and exposing the pump to adverse conditions like running dry, in extended by-pass, freezing, or cavitation coupled with insufficient maintenance will significantly affect how long the pump lasts in actual conditions.

What is a typical pressure washer warranty?

Most pressure washers have a one year warranty which, depending on the type, may have further time restrictions. For example, home owner units may only have a 90 day warranty if the pressure washer is used commercially. Some components, such as engines, pump heads and coils, may have warranties longer than one year. Like most power tools, pressure washer warranties are limited to manufacturing defects. Typically, a factory defect will show up quickly after the pressure washer is put into service. Wear parts, such as: seals, springs, o-rings, etc. are excluded from the warranty. Such parts can wear out in less than one thousand hours of use and must be replace as part of standard maintenance. Improper use will also invalidate the warranty. Examples of improper use include: leaving the pressure washer in bypass too long, cavitating the pump, pumping a liquid other than water through the pressure washer, or freeze damage. The owner's manual should be consulted for specific examples of actions that invalidate the warranty.

What are the key factors in cleaning with a pressure washer?

Use of soap

The most difficult dirt to clean is dirt that has attached to the surface by chemical bonds. Dirt that is just lying on the surface is easy to clean with pressure and flow. In cases where the dirt has bonded with the surface you will need soaps or other cleaning chemicals to efficiently clean.

Soaps and cleaning chemicals have detergents, surfactants, alkaline and acidic compounds. Detergents break down the dirt into smaller compounds, while the surfactants penetrate under the dirt and reduces the forces of attraction so that the dirt becomes loose and can easily be wiped or sprayed off. Surfactants work by lowering the surface tension of water, essentially making it 'wetter' so that it is more likely to interact with oil and grease. Sodium and potassium hydroxide form the basis for most pressure washing detergents. They provide positively charged ions to promote chemical reactions to break the dirt away from the surface to be cleaned. Detergents bond with the dirt and allow them to be picked up by the water from the surface. Acids are used to attack mineral deposits such as metallic stains on concrete. In every case these soaps and cleaning chemicals allow the user to clean substances significantly more effectively. The labor savings are significant. The use of detergents also allows you to use less pressure to clean, reducing the chances of surface damage. This is particularly important when cleaning soft surfaces such as wood or brick.

One step cleaning

In one-step cleaning the soap is applied under high pressure so soap is being applied as the dirt is also being blasted off. This is a fast approach, but can use up soap faster than down-stream injector systems. Many KränzleUSA pressure washers are equipped with high pressure soap injection.

Two step cleaning

When there is a build-up of dirt, the two-step system works best. Apply the soap or detergent in concentrated strength or diluted through the down-stream injector. Let the soap sit or “dwell” on the surface for a few minutes to let the chemicals do their work. Step two: use high-pressure rinse to remove the dirt.

Hot water

Hot water acts to loosen any oil or grease components in the dirt, as well speed up the action of any detergents or cleaning chemicals making cleaning as much as 60% more effective. The more grease, oil or petrochemicals in the dirt, the more important heat is in the cleaning process. We know this from washing dishes, where it is almost impossible to clean a greasy roasting pan with just cold water. It is easier with cold water and soap; and much easier with hot water, and soap.

In the summer, when the surface you are cleaning is warm or hot, a cold water pressure washer and detergent will clean just fine. Once the weather gets cold and the surface you are cleaning is also cold, those cleaning techniques become much less effective. Using a hot water pressure washer will heat the surface to be cleaned, loosen the dirt and make the detergent much more active, speeding the chemical processes involved in emulsifying the dirt.

Hot water pressure washers burn diesel or kerosene to continuously heat the water that has already been pressurized by the pump. The typical heat rise is 120° F. Since most inlet water temperatures are around 60 degrees F, the typical hot water pressure washer can clean with a maximum of 180° F at full pressure and flow. By turning down the unloader, thus reducing the pressure and flow while turning up the temperature to the maximum, you can get a hot water pressure washer to generate a wet steam of up to 240° F. This additional heat will make some types for cleaning more effective, but a true steam cleaner maximizes the cleaning power of steam.

Steam

Most hot water pressure washers are capable of producing steam, by turning down the unloader and turning up the thermostat, but there's a huge difference in the cleaning power of 240° F wet steam of a hot water pressure washer and the 320° F dry steam of a true steam cleaner.

Steam cleaning is an entirely different process. The key to steam cleaning is vapor expansion. The steam cleaner uses steam’s expansion to accelerate water droplets, at the boiling point, to a high velocity. The closer the steam cleaner's nozzle is to the surface to be cleaned, the higher the temperature and velocity of the water/steam mixture, and the more rapid the cleaning action. The temperature of the water/steam mixture drops quickly as the distance between the nozzle and the surface to be cleaned increases. Consequently, for many cleaning applications, the nozzle should be held close to the soiled surface to achieve the best results. Steam cleaners are excellent for cleaning grease and oil, sterilizing, disinfecting, degreasing, dissolving resins, de-icing, flushing away chemicals and poisons, degassing, and for preparing surfaces for painting or other treatments.

Water in a steam cleaner is heated to 320° F at relatively low pressure (in the 100 to 250 PSI range vs. 2,000 to 4,000 psi for the most common pressure washers), depending on the model.

Water at atmospheric pressure boils at 212° F. At higher pressure, it takes more energy to convert water molecules into steam, so the boiling temperature increases. Water in a steam cleaner is compressed to 250 PSI by the pump, and heated to 320° F prior to nozzle discharge. Water at this temperature remains a liquid at any pressure over 89.7 PSI. After the 320° F water in a steam cleaner passes through the restrictive nozzle it is no longer under the additional pressure of the water pump and cannot remain a liquid. Fifteen percent of the water instantly flashes into steam, cooling the mixture of steam and water from 320° F to 212° F. This steam vapor, used with a properly designed steam cleaning nozzle, also accelerates the remaining water droplets. Unlike a pressure washer nozzle, the steam cleaning nozzle has an expansion zone placed past the pressure orifice, which directs the water vapor energy to a smaller area, instead of dissipating in all directions. The tremendous expansion is directed by the conical steam nozzle, accelerating the water droplets. The expansion nozzle's effect can be compared to that of the choke of a shotgun. Not only does the expansion nozzle direct the steam cleaner's output, it serves as a propulsion chamber. The expansion nozzle both directs and accelerates the output.

The cleaning action of steam is not accomplished by a cloud of steam vapor, but by very hot water droplets accelerated by steam expansion in the nozzle. This process allows the water to reach the surface to be cleaned at a temperature as near the boiling point of water as is possible, enhancing the aggressiveness of most cleaning chemicals and making the task of thoroughly removing grease and oil much easier and faster.

Typical applications for steam cleaners include:

- Cleaning engines, transmissions, drive trains, and other equipment prior to performing service and maintenance work.

- Thawing frozen drains, tanks, piping systems, culverts, etc., for street and highway departments, manufacturing and processing plants, pipelines, and other industries.

- Thawing railroad tank cars to accelerate removal of viscous liquid contents, while ensuring that the maximum temperature is less than the boiling point of water (to prevent fires and other high temperature damage).

- Removing chewing gum from sidewalks, tables, stadiums, entryways, etc.

- Degassing tanks prior to welding or other maintenance work, especially gasoline, oil, and petrochemical tanks of all sizes.

- Preparing surfaces for painting, especially removal of cutting oils, grease, and similar oily or greasy substances.

- Degreasing dies and tools in manufacturing operations.

- Removing fats, grease, oils, and substances from surfaces and equipment in food processing plants.

- Melting and removing paraffin and wax or grease from traps and drains in wastewater treatment plants, petroleum refineries, and for similar use in other industries.

- Cleaning and restoring brick, block, stone and other masonry surfaces for maintenance or restoration projects, at monuments, cemeteries, and similar applications, where steam is more gentle and less intrusive and damaging than high pressure cleaning.

Why is proper inlet water flow is important?

Starving a pressure washer of water is one of the best ways to damage a high pressure pump. Since a pressure washer has a positive displacement pump it will attempt to pump the rated amount of water continuously. If the rated amount of water is not provided, a vacuum is created in the pump. To compensate for the lack of water, air from any leaks will be sucked into the pump instead. This will lead to cavitation which quickly destroys the soft components of the pump to include seals, and o-rings. Continued cavitation then goes on to destroy hard components such as valve seats. The force unleashed by cavitation is so great it can even destroy connecting rods, plungers and crack pump heads. This condition can be prevented by insuring that the pump has the rated water available to it and that all plumbing is of proper size and free of leaks. Experts advise that inlet plumbing such as garden hoses be at least 1 1/2 times the size of the water inlet on the pump. Bends, turns, restrictions in valves, an inlet hose of excessive length, can all contribute to put inlet flow. Other negative factors include hot inlet water, turbulence in the water supply, poor inlet water pressure, having the pressure washer on the same level or above a still water source, such a tank, will contribute to poor inlet water flow and lead to damage of the pressure washer. With the exception of the Kränzle pump, most pressure washer pumps do not self prime, so particular care must be taken to insure positive inlet water pressure. Moreover, many KränzleUSA have a built-in water tank to prevent the pump from being accidentally starved of water.

What is nozzle sizing?

It is critical to the efficient performance of your pressure washer to use the correct nozzle size. A pressure washer pump is a positive displacement pump that generates a certain amount of flow. By restricting the flow with a nozzle pressure is created. This nozzle size must match the flow and horsepower of the pressure washer. If the nozzle is too small, the pump and other components of the pressure washer may be damaged through the strain of attempting to push the water through the smaller orifice. If the nozzle is too large, the rated pressure is not obtained and efficiency is lost. You can use a nozzle sizing chart to determine the correct nozzle size. (see chart).

What is an unloader?

An unloader is a valve that "unloads" the pressure when the trigger is not pulled on the gun jet. The flow of water that would ordinarily be forced out the end of the nozzle when the gun jet trigger is pulled is re-routed by the unloader to flow in a loop within the pump head. As there is no water leaving the pump head, the pressure falls to zero on the gauge. This state, when the water is circulating within the pump head at zero pressure is called "bypass". The unloader valve consists of a metal control piston, o-rings, stainless steel check ball and seat, and depending on the design, a non-return valve or stainless steel ball. All these parts receive significant wear and tear as they move under pressure every time you pull or release the trigger of the gun jet. For this reason, the unloader typically wears out faster than any other part of the pressure washer pump. A poorly functioning unloader places undue strain on other components in the pressure washer and can quickly damage the rest of the pump. For this reason, if the unloader begins to malfunction, it should be repaired or replaced immediately. Typical symptoms of a malfunctioning unloader are a sudden loss of pressure, failure to go into bypass smoothly, or not at all, when the trigger is released. There are internal and externally mounted unloaders. Most modern pumps have internal unloaders, built into the side of the pump head. Older or more industrial pressure washers have an external unloader mounted on the side of the pump head with a loop of bypass hose running from the unloader to the water inlet or a tank. The external unloader will typically allow a slightly longer bypass cycle and makes trouble shooting marginally easier, but such set ups are more expensive and more prone to problem causing leaks.

What happens when I leave a pressure washer running in bypass?

When the trigger on the pressure gun jet is released the pressure backs up the hose causing a momentary "spike pressure" in the unloader valve. This sudden increase in pressure shifts the control piston to a position where the water flow is re-routed to loop within the pump head, putting the pressure washer into a state of "bypass". The gauge registers zero, as the water will loop within the pump head indefinitely until the trigger is pulled again. However, the water is being compressed by the pump and rapidly heats up while in the bypass state. If the pump has all ceramic plungers, as most commercial pressure washer do, the ceramic acts as an insulator, keeping the heat trapped within the pump head. After a few minutes the pump head temperature climbs to a level where pump components can be damaged. Many pressure washer are equipped with a thermal relief valve mounted on the side of the pump head. When the internal water temperature climbs to a certain point, usually 145° F, the valve opens up spilling hot water out onto the ground. Fresh, cooler water flows into the pump head from the water inlet, cooling the pump. This saves the soft plastic and rubber parts, such as valve cages, o-rings and seals, within the pump head from being damaged. The flow of cool water can also cause a problem if the ceramic plungers have gotten too hot. The ceramic plungers can crack due to thermal shock with the sudden influx of cold water. For these reasons you are advised not to leave your pressure washer in bypass for more than a few minutes. The one exception to this is the Kränzle pump. The Kränzle pump uses ceramic-coated, stainless steel plungers. These high tech plungers are immune to thermal shock, as well as acting as a conductor of the heat that normally builds up during bypass; allowing the heat to be transferred to the oil bath in the pump transmission housing. This allows the Kränzle pump to stay in bypass far longer than other pump. For details, see the video in YouTube: Why the Kränzle Pump is Superior”.

Is using hot inlet water a good idea?

Hot water cleans better than cold. Sometimes people want use hot inlet water in their inlet cold water pressure washer in an effort to make their cleaning more effective. Hot inlet water can be used, but it typically creates a need for more intensive maintenance on the pressure washer. Most pumps advertise that the highest inlet water temperature they can handle is 140pF. When a pressure washer is spraying with 140° F water the temperature in the pump is near the maximum the soft parts of the pump, seals, o-rings, etc, can reasonably handle without failing prematurely. But, when the pump goes into bypass, the temperature quickly climbs much higher than 140° F, sometimes reaching 200°F, within a matter of minutes, cooking the soft parts of the pump, prematurely wearing them out. This may reduce the life of seals and o-rings to a quarter of the normal time. The customer will notice the oil in the transmission housing getting milky as water begins to slip past the waters seals as they fail. The oil must be changed immediately, and probably the water seals as well. Sometimes this extra maintenance expense is worth the labor savings that results from the more efficient cleaning that comes with using hot water. If a pressure washer user wants to use inlet hot water they must be prepared to perform more maintenance on their pressure washer and check the oil in the pump transmission regularly to make sure that the oil is not contaminated or getting milky.

What is the difference between high and low pressure injection?

Most pressure washer can pull cleaning chemicals into the stream of water by using an injector. Most commonly, this injector is "downstream" or after the pump. Downstream injectors inject the soap at low pressure, typically 200 PSI. This is done by installing a soap injector after the pump and placing a large orifice nozzle on the pressure washer. Since the water is less restricted by the larger nozzle, it picks up velocity and the extra flow causes a slight suction in the injector body. This suction action picks up the soap via tube coming from the injector that is placed in the chemical container. After applying the soap, the user switches to a small orifice, high pressure, nozzle for the rinse phase. This system has the advantage of keeping the soap, or cleaning chemical, from going through the pump head, and being able to tightly control the amount of soap applied to the surface to be cleaned. Another method of soap application through a pressure washer is high pressure soap. Only a few pressure washers are equipped to apply soap in this manner. The soap is fed into through the pressure washer pump and applied at high pressure. There is no need to change nozzles; the application is controlled by turning a valve. This one step application is faster and insures that the soap if fully agitated on the surface. Many KränzleUSA pressure washers are equipped with high pressure soap.

How do users commonly damage their pressure washers?

All pressure washers are high maintenance machines. High-pressure water will eventually wear out seals, o-rings, springs, and other parts that make up a high pressure cleaner. As the owner of a power washer, no matter the quality, you can expect to have to replace seals, valves, and O-rings as well as change the oil as part of routine maintenance. However, what causes extra high maintenance costs are the problems that result from operator error.

Problem 1. Running the pressure washer without water.

Normally this will destroy the high pressure pump within minutes. Without water to cool the pump head and lubricate the seals, the temperature quickly rises cooking pump components. The exception is the Kränzle pump. This pump can run for at least one hour without water without damaging the pump.

Problem 2. Running the pressure washer in extended by-pass.

By-pass is when the pressure washer is on, but you are not pulling the trigger of the gun-jet, so the water is re-circulating within the pump. In this state, the water temperature in the pump head builds as time goes on. If you look at the warranty card for most small electric home owner type pressure washers sold, it would state that if you run the unit in by-pass for more than five minutes you invalidate the pump warranty. This is because the heat buildup quickly damages the pump. Therefore, you have the hassle of turning off the pressure washer every time you are not going to be spraying. For commercial units, they overcome this problem by installing a thermal relief valve that dumps water from the pump onto the ground after a few minutes in an effort to cool the pump when left too long in by-pass. If the thermal relief valve fails, your pump can be badly damaged. Pressure washers that use the Kränzle pump, that has a unique design that allows it to run safely in by-pass for over an hour, is an exception to this.

Problem 3. Cavitation.

Cavitation is caused by air getting into your pump. The air can damage your pump as it rapidly expands and contracts. The first sign of cavitation is loss of pressure and a hammering noise. The cause of cavitation is inadequate water supply or the introduction of air into the system. For example, a pressure washer rated to pump 4.2 gallons per minute (GPM) will still try to pump that amount of water even if the inlet water flow only is only allowing 3 GPM. The suction due to the lack of water will create an internal vacuum and cause cavitation. A hole in the inlet water hose can also cause cavitation, as the pump will sometimes suck in extra air. The only solution to cavitation is to feed your pump the required amount of water and to make sure there are no leaks in the water inlet system.

Problem 4. Freezing.

If you live in a cold climate, and let your pressure washer freeze with water left in the pump from the last use, there is possibility of damage to the pump. The typical remedy for this is putting anti-freeze in the pump. The Kränzle pump is freeze proof; the unit can freeze, be thawed, and still sustain no damage. Leaving a pressure washer in an unheated garage during the winter often leads to freeze damage.

Problem 5. Lack of lubrication.

High-pressure pumps, like gasoline engines, require oil to lubricate the plungers in the backend of the pump opposite the pump head. The forces generated in the pump are large, causing friction and heat. Clean oil is needed to keep the pump parts cool and turning freely. If oil is allowed to leak out, or water gets into the pump oil, the pump parts will overheat and begin to break apart. Always check your oil level and condition; maintain the correct amount and type of oil in the pump to prevent damage.

Problem 6. Leaks.

A pressure washer is designed to be a closed system with only two openings: the inlet for incoming water, and the nozzle for the spraying out the high pressure water. Leaks, whether internally within the pump, or externally, at the machine, inlet, or the high pressure end, cause problems and will damage the pressure washer over time. Any leak needs to be repaired immediately to prevent the potential of damage to the pressure washer. Repair a leak now, by replacing a ten cent o-ring, can prevent a $200 repair bill for new seals later.